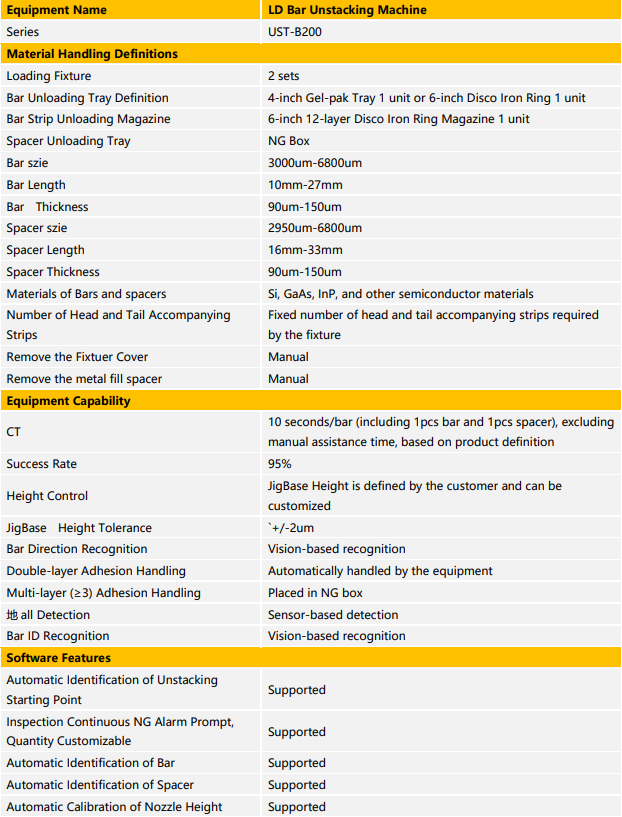

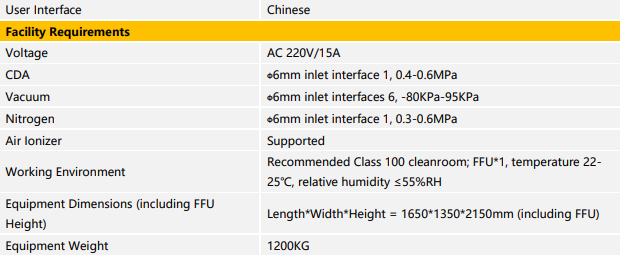

Fully Automatic De-bar Machine

Fully Automatic De-bar Machine

Unstacking the LD bar after coating and transfer to Gel-pak tray or tape.

Product Inquiry Hotline:+86-138-1192-8592(Mr. Mao)

Product Inquiry Email: jian.mao@incubecn.com

Product Inquiry Hotline:+86-138-1192-8592(Mr. Mao)

Product Inquiry Email: jian.mao@incubecn.com

Product Introduction: The machine can unstacking the LD bar after coating and transfer to Gel-pak tray or tape. More over it can recognize the Chip ID.

Bar and Spacer Materials: Si, GaAs, InP, and other semiconductor materials.

Previous:

Multi Die Bonder