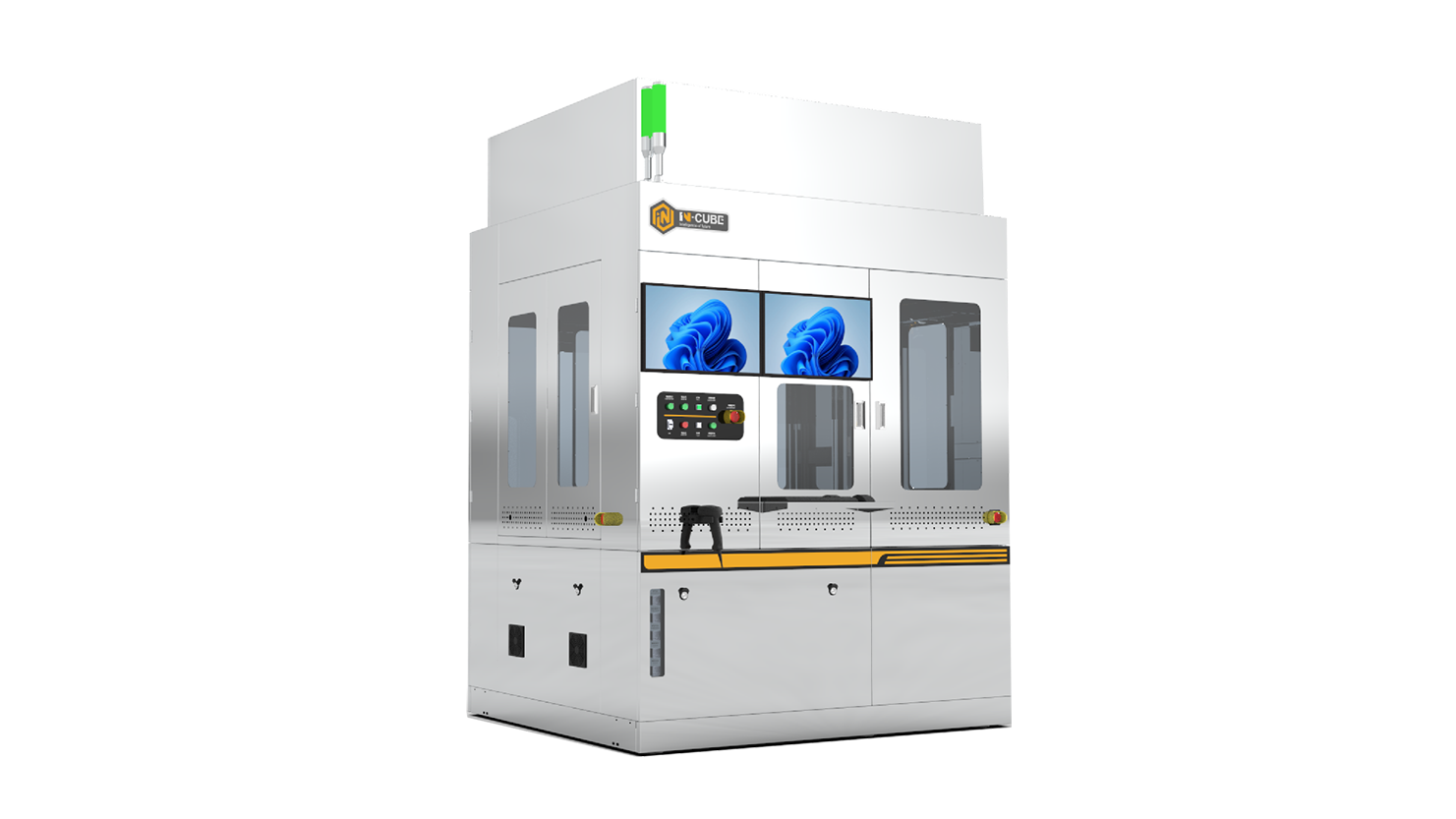

MS-WTW Wafer Inspection and Sorting Machine

MS-WTW Wafer Inspection and Sorting Machine

The MS-WTW Wafer Inspection and Sorting Machine is mainly used for AOI multi-surface inspection and sorting of individual chips after wafer dicing, with the chips placed from one blue film to another.

Product Inquiry Hotline:+86-138-1192-8592(Mr. Mao)

Product Inquiry Email: jian.mao@incubecn.com

Product Inquiry Hotline:+86-138-1192-8592(Mr. Mao)

Product Inquiry Email: jian.mao@incubecn.com

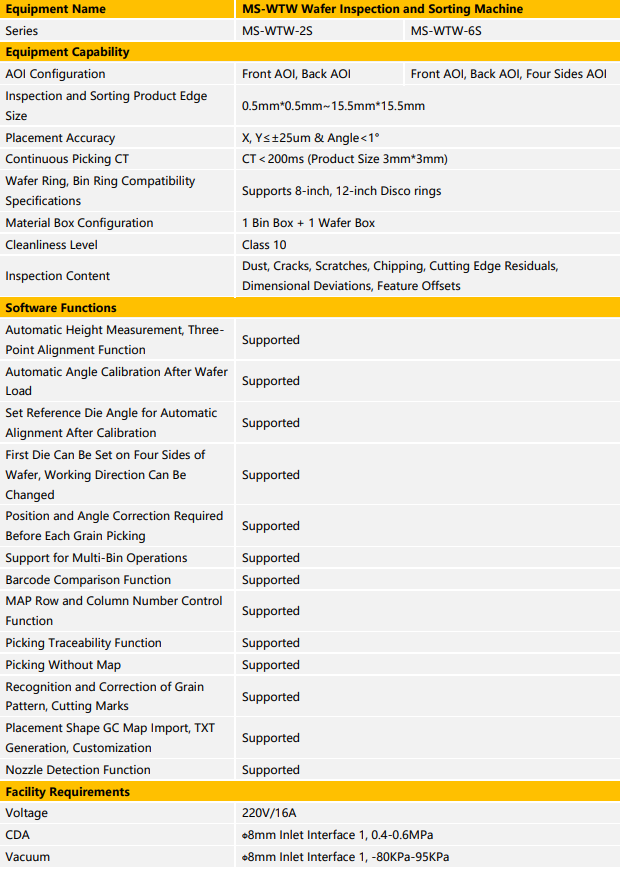

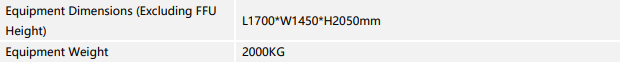

The MS-WTW Wafer Inspection and Sorting Equipment is an automated system designed for membrane-to-membrane processing, combining inspection and sorting functions. It features high pick-and-place speed, high die bonding accuracy, high inspection precision, and high cleanliness levels. It is compatible with incoming 8-inch and 12-inch Disco rings and can handle chip products ranging from 0.5mm * 0.5mm to 15.5mm * 15.5mm in size.

Previous:

Mini/Micro LED Chip Sorter

Next:

Multi Die Bonder